Pneumatic conveying, at its core, is a straightforward concept—how to efficiently transfer products from point A to point B. However, troubleshooting these systems can sometimes feel like a formidable task. In this guide, we aim to simplify the process by breaking down the four primary components of any conveying system, identifying common issues, and providing guidance on what to check for. The essential components are a blower package, convey line, filter receiver/bin vent, and a rotary airlock valve. Common problems include product build-up in convey lines or airlock valves, erratic feed rates, wear on elbows or airlocks, and an increased frequency of line blockages.

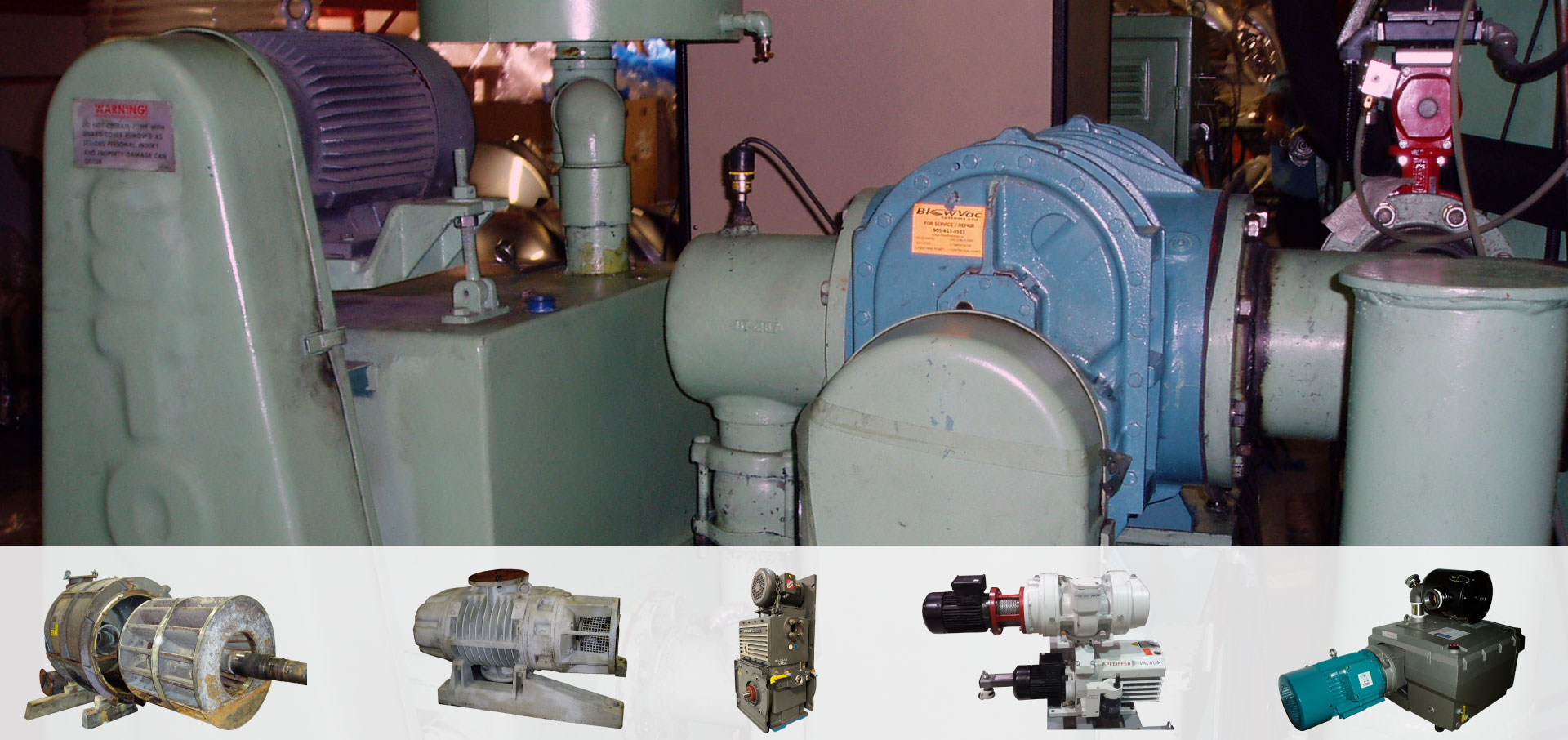

Blower Packages:

Blower packages, representing about 1% of field problems, are usually trouble-free if properly sized. Generally, a well-maintained blower package that runs smoothly in the first week of installation is likely to continue functioning for the next two decades. Monitoring pressure changes is crucial during troubleshooting. Historical pressure data on the blower package serves as an excellent indicator of issues within the conveying system. Refer to the chart below for key indicators and associated problems.

| Indicator |

Issue |

| Low Pressure |

Possible feed problems |

| High Pressure |

Build-up in convey lines |

| Bouncing Pressure |

Erratic feed rate/worn-out airlock |

| PRV Popping Off or High-pressure shutdown |

Plugged convey lines |

Convey Lines:

Convey lines, contributing to around 5% of field problems, pose challenges related to product wear and line build-up. Elbows, or sweeps, are susceptible to wear, causing leaks when handling abrasive products. Wear typically occurs near the end of the transfer system where convey velocities are highest. Line blockages due to product build-up are evident when operating pressures are higher than normal. Physically inspecting the conveying lines can also provide insights.

| Indicator |

Issue |

| High Pressure |

Product build-up/Plugged convey lines |

| Can’t feel product transfer |

Product build-up/Plugged convey lines |

| Material escaping from lines |

Leak in line couplings or hole in elbow |

Filter Receivers and Bin Vents:

Filter receivers and bin vents, accounting for approximately 5% of field problems, are often misconstrued as "dust collectors." Their primary purpose is to separate product and air. Common issues include dirty filter bags/cartridges or failed solenoids/diaphragms. Monitoring the timer board during troubleshooting provides valuable information about cleaning pulses, differential pressure, and other critical functions.

| Indicator |

Issue |

| Fluctuating Differential Pressure |

Bags need cleaning or replacement |

| Inconsistent Filter Pulses |

Bad solenoid or diaphragm |

| No Differential Pressure Indication |

Filter instrument media is plugged or installed incorrectly |

Rotary Airlocks:

The remaining 89% of typical problems are often attributed to rotary airlocks. These precision devices, operating in demanding environments, have varying tolerances depending on the manufacturer. Wear on a rotary valve is internal and occurs gradually, making detection challenging. Indicators and associated issues are outlined below.

| Indicator |

Issue |

| Conveying rate drop |

Rotary Valve Wear |

| Frequency of line blockages |

Product Build-up in Rotor pockets |

| Bouncing blower pressure |

Product build-up on airlock bore/housing |

In conclusion, there are four main components in your system that could be causing conveying issues—blower package, convey lines, filter receivers/bin vents, and airlocks. While each piece provides potential clues, starting with the airlock is often the most effective approach.

Learn More with BlowVac Systems

If you need assistance troubleshooting your system, replacing your airlock, or upgrading your entire pneumatic transfer system, contact us