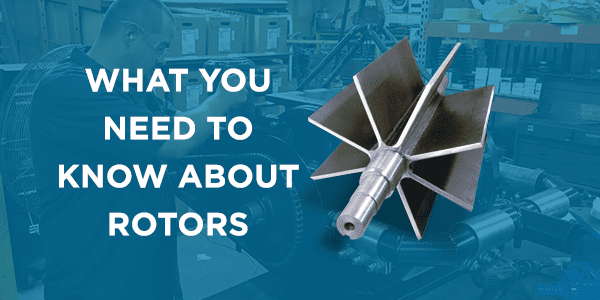

Selecting the appropriate rotor for your rotary airlock valve is crucial for optimal performance and longevity. The choice of rotor significantly impacts valve life, efficiency, and overall operation. Incorrect selection may lead to issues such as accelerated wear, premature failure, increased downtime, reduced efficiency, heightened maintenance requirements, product degradation, and potential production losses.

With Blowvac Systems airlock product line, two main rotor designs are offered: open end rotors and closed end rotors. These designs, along with various modification options, aim to enhance operation, meet feed rates, and prevent wear. Factors like product application, flow characteristics, abrasiveness, and feed rate play pivotal roles in determining the best rotor design, modification option, material of construction, and coating needed for optimal results in your bulk material handling system.

Rotor Types for Your Airlock:

- Open End Rotors

Open end rotors, suitable for applications not requiring abrasion-resistant construction, offer cost savings and slightly higher capacity than closed end rotors. They are standard on our Type 1, 3, 4, and 5 style airlock valves.

- Closed End Rotors

Best suited for applications requiring abrasion-resistant construction, closed end rotors are standard on our Type 2 and 8 style airlock valves. For added protection against abrasive products, our patented cavity air purge system (CAP) is available for pressure system applications.

Abrasion-Resistant Tips and Materials of Construction:

- Bolt-On Abrasion Resistant Tips (Provided on Type 2): 400 Brinell hardness replaceable tips.

- Tungsten Carbide Tile Tips (Provided on Type 8): 69-70 Rc hardness.

- Materials of Construction:

- Carbon Steel Rotors: Standard for most airlocks, suitable for various materials.

- 304 Stainless Steel Rotors: Standard for Type 4 valve, for handling food or mildly corrosive materials.

- 316 Stainless Steel Rotors: Standard for Type 5 valve, for handling extremely corrosive materials.

Rotor Modification and Tip Options:

- Reduced Capacity Rotors

Adjusting rotor capacity is necessary for products with specific flow properties and low feed rate requirements. This modification can be applied to open or closed end rotors to meet lower feed rates without compromising metering consistency.

- Relieved Tip Rotors

Designed to minimize product buildup, relieved tip rotors are ideal for materials prone to sticking on airlock feeder surfaces. This design reduces noise with certain powder materials by preventing friction between the rotor and housing.

- Flex Tip Rotors

Featuring a flexible tip design, these rotors prevent material jams between rotor tips and housing. Standard tips are made of thermoset polyurethane and are replaceable. Optional tips include food-grade white neoprene, black neoprene, and heavy-duty conveyor belting. Flex tips can be installed on closed or open end rotors.

Coating and Finishing Options:

- Nedox: Superior resistance against wear, corrosion, and friction with a surface hardness up to 68 Rc, suitable for moderately abrasive sticky materials.

- Teflon Coated: An economical solution for applications involving sticky materials.

- Hard Chrome: Applied to improve wear and abrasion resistance, reduce friction, prevent seizing, and galling.

With over 40 years of experience, Blowvac Systems has been a trusted manufacturer of pneumatic conveying systems, components, and rotary airlock valves, ensuring the design and engineering of quality material transfer systems.

Learn More with BlowVac Systems

Do you have questions about the airlock valve? Would you like an in-depth service or repair ?